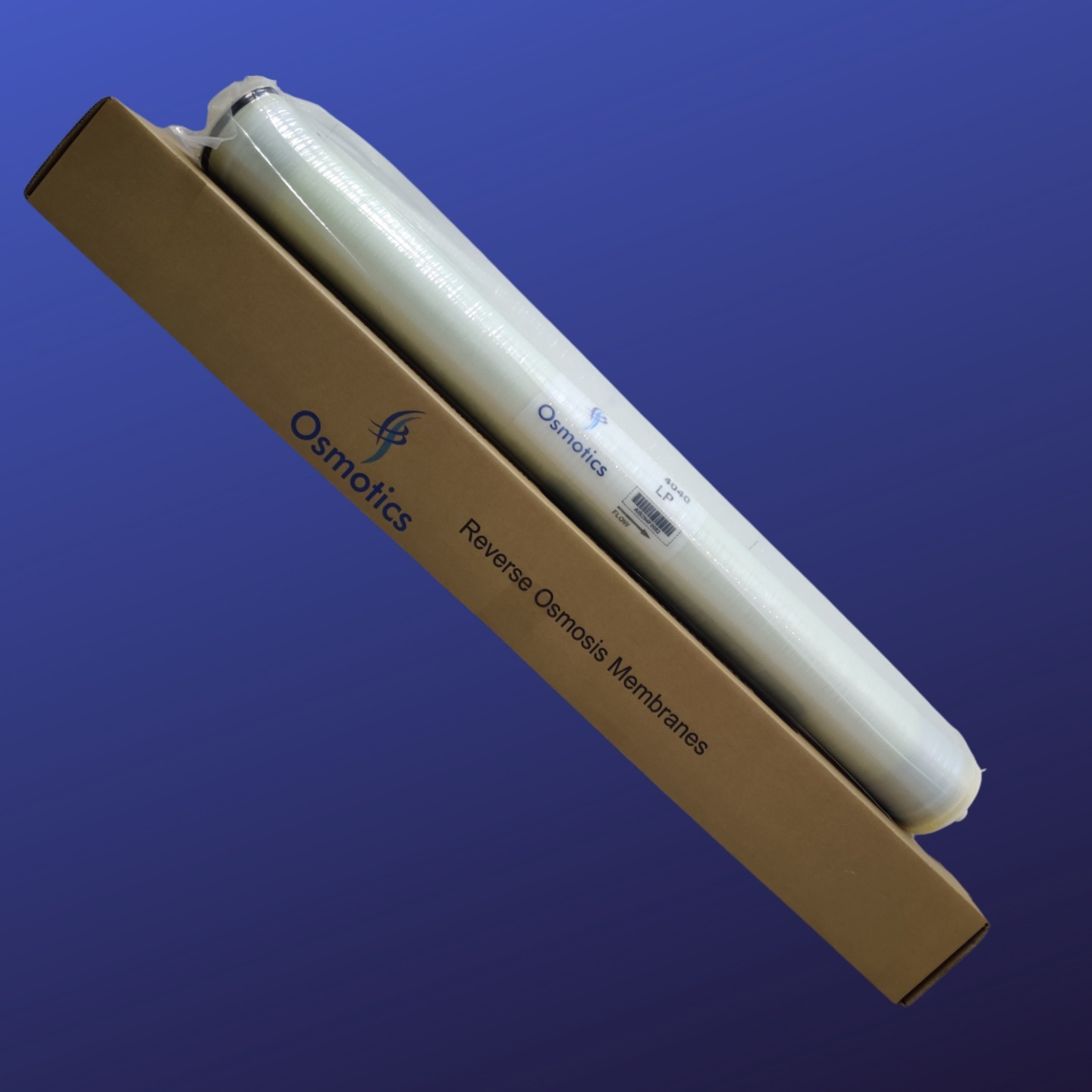

RO MEMBRANE ELEMENT 4040 ULP Osmotics

Osmotics ULP 4040 Membrane: Advanced Ultra-Low Pressure Filtration

Specified Performance

- Permeate Flow: 2,400 gpd (9.1 m³/d)

- Salt Rejection: 99.5% (99.2% minimum)

- Test Conditions: 1500 ppm NaCl solution

100 psig (0.69 MPa) Applied Pressure

77°F (25°C) Operating Temperature

15% Permeate Recovery

pH Range: 6.5 - 7.0

The specified performance is based on data collected after a minimum of 10 minutes of operation. Individual permeate flow rates may vary by ±15% from the specified value. Performance is normalized to these standard conditions.

General Product Description

- Configuration: Spiral Wound

- Membrane Polymer: Composite Polyamide

- Membrane Active Area: 85 ft² (7.9 m²)

- Recommended Use: Suitable for ultra-low pressure brackish water applications with feedwater TDS up to 2000 ppm (Terms and conditions applied)

- Packaging: Each membrane element is equipped with a brine seal, interconnector, and O-rings. Sealed in a polyethylene bag with less than 1.0% sodium meta-bisulfite solution and packaged in a cardboard box.

Element Details

- Core tube extension: 1.05" (26.7 mm)

Product Use and Restrictions

- Maximum Applied Pressure: 600 psig (4.14 MPa)

- Maximum Chlorine Concentration: < 0.1 ppm

- Maximum Operating Temperature: 113°F (45°C)

- pH Range, Continuous (Cleaning): 2-10 (1-12)

- Maximum Feedwater Turbidity: 1.0 NTU

- Maximum Feedwater SDI (15 mins): 5.0

- Maximum Feed Flow: 16 gpm (3.6 m³/h)

- Minimum Brine Flow: 3 gpm (0.7 m³/h)

- Maximum Pressure Drop for Each Element: 15 psi (0.10 MPa)

^These limitations are for general use. More conservative values may enhance membrane performance and lifespan. Refer to Osmotics Technical Bulletins for further specifications and operational guidance.

Disclaimer: This information is shared in good faith, without warranties. Implied warranties, such as merchantability or fitness for a particular purpose, are disclaimed. The user is responsible for determining product suitability for specific applications. Osmotics assumes no liability for outcomes from product application based on this information.

Osmotics ULP 4040 Membrane: Advanced Ultra-Low Pressure Filtration

Specified Performance

- Permeate Flow: 2,400 gpd (9.1 m³/d)

- Salt Rejection: 99.5% (99.2% minimum)

- Test Conditions: 1500 ppm NaCl solution

100 psig (0.69 MPa) Applied Pressure

77°F (25°C) Operating Temperature

15% Permeate Recovery

pH Range: 6.5 - 7.0

The specified performance is based on data collected after a minimum of 10 minutes of operation. Individual permeate flow rates may vary by ±15% from the specified value. Performance is normalized to these standard conditions.

General Product Description

- Configuration: Spiral Wound

- Membrane Polymer: Composite Polyamide

- Membrane Active Area: 85 ft² (7.9 m²)

- Recommended Use: Suitable for ultra-low pressure brackish water applications with feedwater TDS up to 2000 ppm (Terms and conditions applied)

- Packaging: Each membrane element is equipped with a brine seal, interconnector, and O-rings. Sealed in a polyethylene bag with less than 1.0% sodium meta-bisulfite solution and packaged in a cardboard box.

Element Details

- Core tube extension: 1.05" (26.7 mm)

Product Use and Restrictions

- Maximum Applied Pressure: 600 psig (4.14 MPa)

- Maximum Chlorine Concentration: < 0.1 ppm

- Maximum Operating Temperature: 113°F (45°C)

- pH Range, Continuous (Cleaning): 2-10 (1-12)

- Maximum Feedwater Turbidity: 1.0 NTU

- Maximum Feedwater SDI (15 mins): 5.0

- Maximum Feed Flow: 16 gpm (3.6 m³/h)

- Minimum Brine Flow: 3 gpm (0.7 m³/h)

- Maximum Pressure Drop for Each Element: 15 psi (0.10 MPa)

^These limitations are for general use. More conservative values may enhance membrane performance and lifespan. Refer to Osmotics Technical Bulletins for further specifications and operational guidance.

Disclaimer: This information is shared in good faith, without warranties. Implied warranties, such as merchantability or fitness for a particular purpose, are disclaimed. The user is responsible for determining product suitability for specific applications. Osmotics assumes no liability for outcomes from product application based on this information.